The Process of Using Spray Foam: What You Required to Know

Leading Reasons to Select Spray Foam for Your Following Insulation Project

When thinking about insulation choices for your following job, spray foam stands out due to its excellent efficiency attributes and efficiency advantages. As you evaluate your options, checking out the flexible applications and long-lasting advantages of spray foam may reveal engaging factors to include it right into your insulation technique.

Superior Insulation Efficiency

The high R-value of spray foam, which determines its thermal resistance, is an additional essential benefit. Closed-cell spray foam, for example, can attain an R-value of up to 6.5 per inch, dramatically surpassing fiberglass batts and cellulose. Spray foam insulation creates an impermeable seal, which reduces thermal linking and reduces the capacity for mold and mildew development due to moisture accumulation.

Energy Performance Benefits

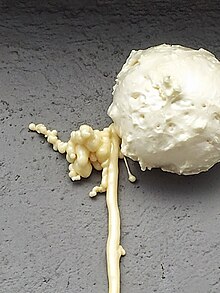

The energy efficiency advantages of spray foam insulation are substantial, more improving its charm as a top choice for constructing insulation. Among the main advantages is its superior thermal efficiency. Spray foam increases upon application, producing a closed seal that reduces air leaks, which is an usual source of energy loss in traditional insulation products. By successfully minimizing thermal bridging, it keeps a regular indoor temperature level, therefore reducing heating & cooling expenses.

Furthermore, spray foam insulation flaunts a high R-value per inch, which indicates it provides a lot more thermal resistance in less area contrasted to options like fiberglass or cellulose (Spray Foam). This efficiency not only adds to instant power cost savings yet likewise advertises long-term sustainability by lowering the general power consumption of a structure

Additionally, the execution of spray foam can qualify homeowners for energy performance incentives and tax obligation credit histories, including financial advantages to its energy-saving capabilities. In an age where power preservation is critical, choosing spray foam insulation not just enhances comfort yet also lines up with eco accountable techniques, making it a prudent option for both commercial and property projects.

Wetness and Mold And Mildew Resistance

Given its distinct structure and application approach, spray foam insulation supplies phenomenal dampness and mold resistance, making it a suitable choice for various atmospheres. The closed-cell structure of spray foam produces a strong obstacle that properly secures off possible moisture access, thereby decreasing the possibility of mold growth. Unlike standard insulation products, which can take in water and give a reproduction ground for mold and mildew, spray foam continues Discover More to be unsusceptible moisture, enhancing the overall health and wellness of the indoor atmosphere.

Furthermore, the application process of spray foam involves expanding and loading splits and voids, making sure a limited seal that minimizes air leaks. This characteristic not just boosts power effectiveness however likewise assists control humidity levels within the room. Correct humidity control is important for protecting against mold and mildew and mold, making spray foam insulation specifically useful in areas prone to wetness, such as cellars and crawl spaces.

Along with its moisture-resistant homes, spray foam is likewise inherently immune to mold and mildew development. This particular ensures that homes and buildings stay risk-free and healthy in time, offering peace of mind to home owners and building supervisors alike.

Long-Term Expense Savings

Buying spray foam insulation returns substantial long-lasting cost financial savings, primarily with enhanced power efficiency. Unlike standard insulation materials, spray foam produces an impermeable sites seal that reduces air leak. This decrease in drafts leads to decrease cooling and heating prices, as a/c systems do not need to work as hard to keep comfortable interior temperature levels.

Additionally, the premium protecting residential properties of spray foam imply that homes continue to be consistently comfortable year-round, minimizing dependence on energy-consuming appliances. Gradually, these financial savings can build up, causing a visible reduction in energy expenses.

Additionally, spray foam insulation adds to the durability of your home's framework by preventing wetness build-up and mold and mildew development, which can lead to expensive fixings. With its resilience and resistance to working out, spray foam preserves its effectiveness throughout the years, making sure that the first financial investment remains to pay off.

Fundamentally, selecting spray foam insulation not only improves your home's energy effectiveness yet additionally converts right into significant long-term monetary benefits, making it a smart financial investment for house owners aiming to additional reading reduce prices while boosting convenience and sustainability.

Versatile Application Options

Numerous application options make spray foam insulation a highly versatile option for a range of building projects (Spray Foam). This adaptability allows it to be effectively utilized in residential, commercial, and commercial setups, providing to diverse insulation requirements

Spray foam can be used in attics, wall surfaces, crawl spaces, and even roof coverings, giving smooth protection that gets rid of gaps and spaces where air leaks commonly occur. Its ability to increase upon application makes sure a tight seal, which is important for power effectiveness and wetness control.

Moreover, spray foam insulation is readily available in various formulations, consisting of open-cell and closed-cell types, permitting customized solutions based upon certain project needs. Open-cell foam is lighter and much better matched for soundproofing, while closed-cell foam uses superior insulation and architectural stability, making it perfect for locations subjected to dampness.

In addition, spray foam can be used in hard-to-reach areas, enhancing its suitability for retrofitting existing frameworks. With the capability to abide by various substratums, consisting of metal, concrete, and timber, spray foam insulation attracts attention as a flexible alternative that fulfills the demands of contemporary structure practices.

Conclusion

In final thought, spray foam insulation emerges as an exceptional option for insulation projects due to its remarkable thermal resistance, energy performance, and capability to produce airtight seals that prevent dampness and mold development. Picking spray foam insulation makes sure an extensive service that fulfills the needs of contemporary construction and power effectiveness standards.

When it comes to attaining ideal energy performance in business and property buildings, spray foam insulation stands out for its superior insulation efficiency.The energy performance benefits of spray foam insulation are substantial, additional boosting its charm as a top option for building insulation.Spending in spray foam insulation yields substantial long-term price savings, primarily with enhanced power efficiency.In final thought, spray foam insulation emerges as a remarkable option for insulation jobs due to its remarkable thermal resistance, power efficiency, and capacity to create closed seals that prevent wetness and mold development. Selecting spray foam insulation makes sure a thorough option that meets the needs of modern building and power efficiency requirements.